Smart Glass Co., Ltd. —— China's leading PDLC film manufacturer

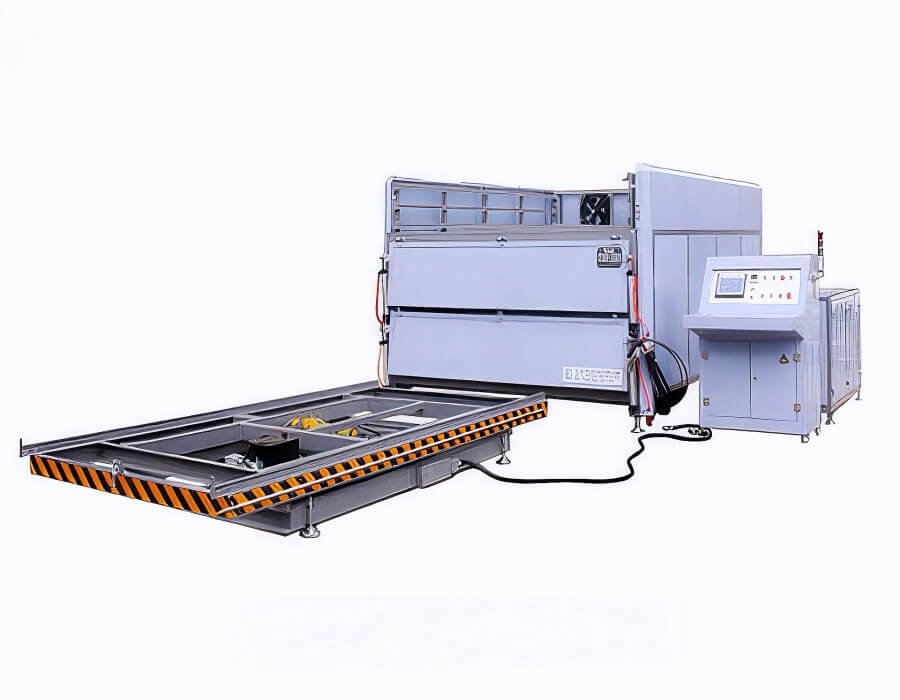

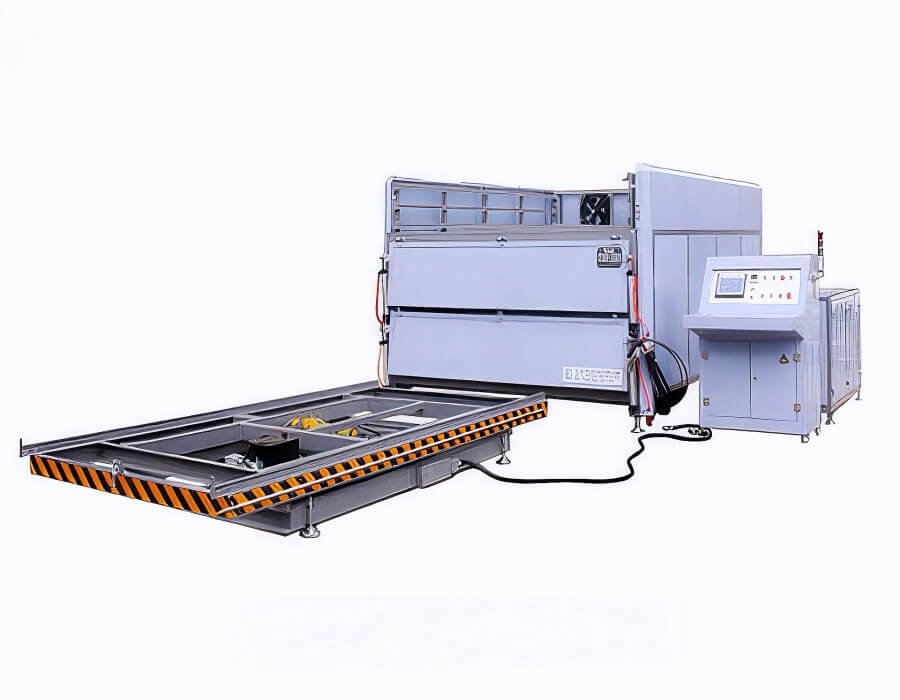

Smart Glass Lamination Oven ★★★★★

PRODUCT PARAMETERS

Smart Glass Lamination Oven ★★★★★

- Voltage: 220V ~ 380V

- Power: 45kW

- Heating: Rapid and uniform heating

- Glass Type: Suitable for large curved glass

- Control System: Siemens PLC

- Operation Mode: Single/double station switchable

Description

FAQs

Request A Quote

Description

High Efficiency, Precision, and Flexibility for Smart Glass Production

Our Smart Glass Laminating Furnace is designed to meet the growing demands of smart glass manufacturing. With a unique dual-track design, the furnace can operate in both single-station and double-station modes, providing flexibility to handle different production needs. It is ideal for producing large curved laminated glass for architecture, as well as various other types of smart glass.

Key Advantages for Smart Glass Production

- Dual-Track Design for Flexibility

The dual-track system allows the furnace to run in single or double-station mode. This flexibility boosts production efficiency and can accommodate both small and large production runs. - Suitable for Large Curved Glass

This furnace can easily handle large curved architectural glass, ensuring precise lamination even for complex shapes and sizes. - Fast and Even Heating

The furnace heats up quickly and evenly, ensuring consistent temperature throughout the glass for high-quality lamination without defects like bubbles or warping. - Energy-Efficient

With a power rating of 45kW, the furnace is designed to be energy-efficient, reducing production costs while maintaining high performance. - Precise Control for Consistent Quality

The furnace is equipped with advanced control systems to manage temperature, pressure, and time, ensuring consistent and reliable results for every batch of smart glass.

Core Features

- Pressure Vessel

Ensures uniform pressure during the lamination process, resulting in smooth, bubble-free glass. - High-Performance Motor and Pump

Provides reliable power and pressure, ensuring stable operation throughout the production process. - Siemens PLC Control System

Easy-to-use Siemens PLC system for precise and automated control of key production parameters like temperature, pressure, and time.

Technical Specifications

- Voltage: 220V ~ 380V

- Power: 45kW

- Heating: Fast, uniform heating system

- Core Components: Pressure vessel, motor, Siemens PLC, pump

- Glass Size: Suitable for various sizes, especially large curved glass

Applications

- Building Industry

Ideal for producing smart dimming glass, solar control glass, and curved laminated glass used in architectural applications like facades and skylights. - Automotive and Aerospace

Perfect for producing curved smart glass for vehicles and aircraft. - Other Applications

Suitable for making solar glass, energy-efficient glass, and other types of smart glass used in various industries.

Why Choose Our Smart Glass Laminating Furnace?

- Boost Efficiency: Dual-track design and fast heating reduce production time, improving overall efficiency.

- Consistent Quality: Precise control systems ensure high-quality lamination with minimal defects.

- Energy-Saving: The furnace is designed to reduce energy consumption, helping to lower operational costs.

- Versatile: It can handle a variety of glass types, sizes, and shapes, making it perfect for a wide range of applications.

- Easy to Use: The Siemens PLC control system simplifies operation and ensures automated, reliable results.

Our Smart Glass Laminating Furnace is the perfect solution for producing high-quality smart glass with flexibility and efficiency. Whether you are making architectural glass, automotive glass, or any other type of smart glass, our furnace offers reliable, high-performance production.

FAQs

How do I choose between smart film and smart glass?

When choosing between smart film and smart glass, consider the following factors:

- Application: Smart glass is ideal for new constructions or major renovations, while smart film can be retrofitted onto existing glass surfaces.

- Cost: Smart film is generally more cost-effective and easier to apply than smart glass.

- Aesthetics: Smart glass offers a seamless, integrated appearance, while smart film can be applied to a variety of glass types.

- Functionality: Both provide similar benefits, but smart glass may offer more advanced features and better long-term durability.

- Installation: Smart film is easier and quicker to install, whereas smart glass may require professional installation.

Evaluate your specific needs, budget, and installation requirements to make the best choice.

Can smart film/smart glass be customized in size?

Yes, both our smart films and smart glass can be customized to meet specific customer needs, including size, shape and functional configuration. For smart films, you only need to provide the actual size or visible light size of the glass. For custom smart glass, we need you to provide details such as upper and lower groove depth, left and right groove depth, groove width, and visible light size of the glass.

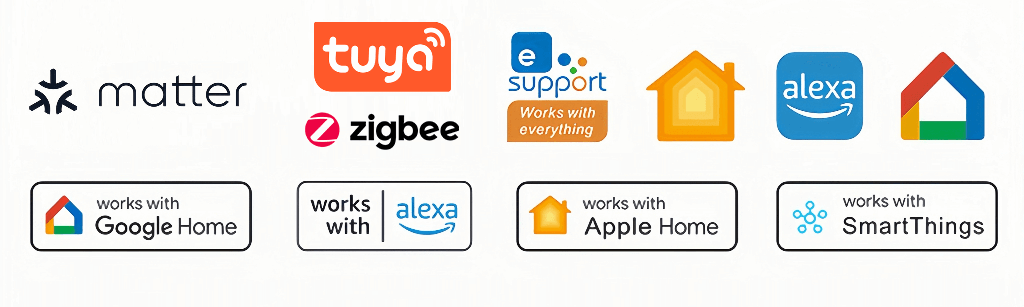

How can smart glass and smart film be controlled? Can they be integrated with smart home systems?

Smart glass and smart film can be controlled in several ways, including wall switches, remote controls, or integration with smart home systems. When integrated with a smart home system, you can control the transparency and other features through mobile apps or voice commands using platforms like Google Assistant, Apple HomeKit, or Amazon Alexa.

Our products currently support the following smart home platforms and protocols:

- Matter

- Esupport Works with Everything

- eWeLink

- Works with Google Home

- Works with Apple Home

- Works with Alexa

- Zigbee

- Tuya

These versatile control options allow smart glass and smart film to seamlessly integrate into your smart home environment, providing convenience and flexibility.

What payment methods do you accept?

We support payments through local accounts in over 20 countries, accept more than 50 currencies, and facilitate transactions in over 100 countries. This ensures secure and efficient payment options for our global customers. We accept various payment methods including Visa, MasterCard, American Express, Discover, PayPal, JCB, Diners Club, and UnionPay. For more details or specific payment inquiries, please contact us.

What are your shipping options and delivery times?

We offer air, land, and sea freight options based on your location. Delivery times depend on the order volume, with smaller orders typically shipping within 1-2 days. For precise shipping times and options, please contact us with your specific requirements.