Smart Glass Co., Ltd. —— China's leading PDLC film manufacturer

Smart Film manual cutting machine ★★★

PRODUCT PARAMETERS

Description

FAQs

Request A Quote

Description

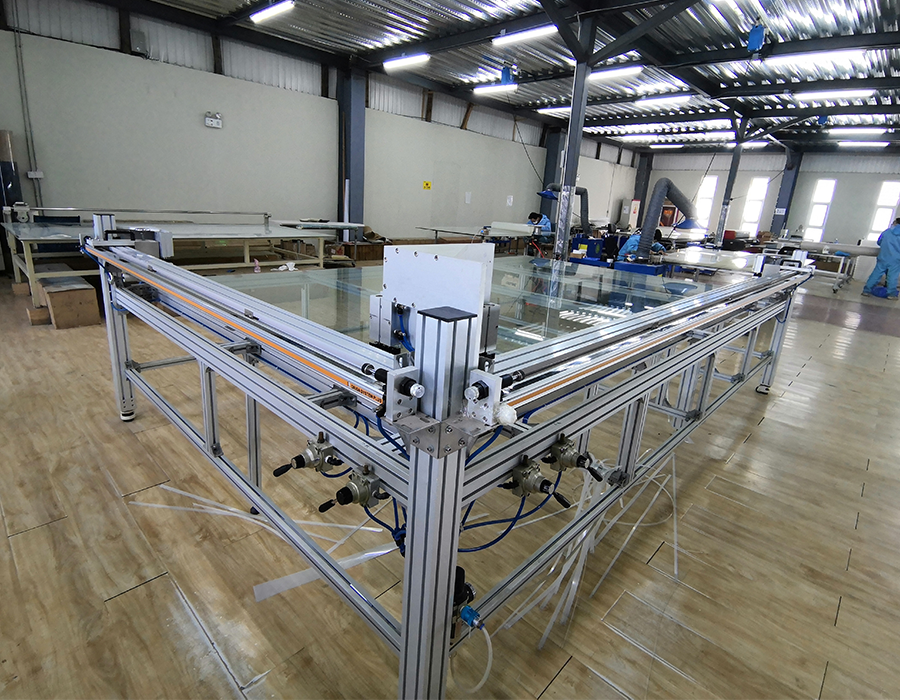

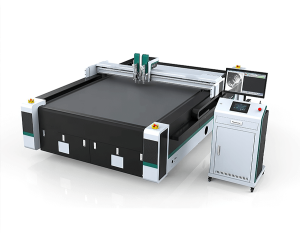

Smart Film Manual Cutting Machine

Overview:

The Smart Film Manual Cutting Machine is specifically designed for the precise straight-line cutting of smart film (electrochromic film), plastic sheets, and other thin film materials. Widely used in industries such as electronics, automotive, and construction, it ensures high precision and efficiency in cutting, making it an essential tool in the production process.

Product Features

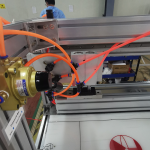

- High Precision Cutting:

The machine adopts an upper and lower knife cutting design, with the lower knife made of special mold steel and the upper knife featuring a rolling circular blade. This design ensures that cuts are clean, without burrs or delamination, providing high-quality cutting results. - Easy Adjustment and Maintenance:

The upper knife is mounted on a rolling linear bearing, which allows for easy replacement and adjustment. The machine is simple to operate and adjust, ensuring smooth and efficient production. - Durable and Attractive Construction:

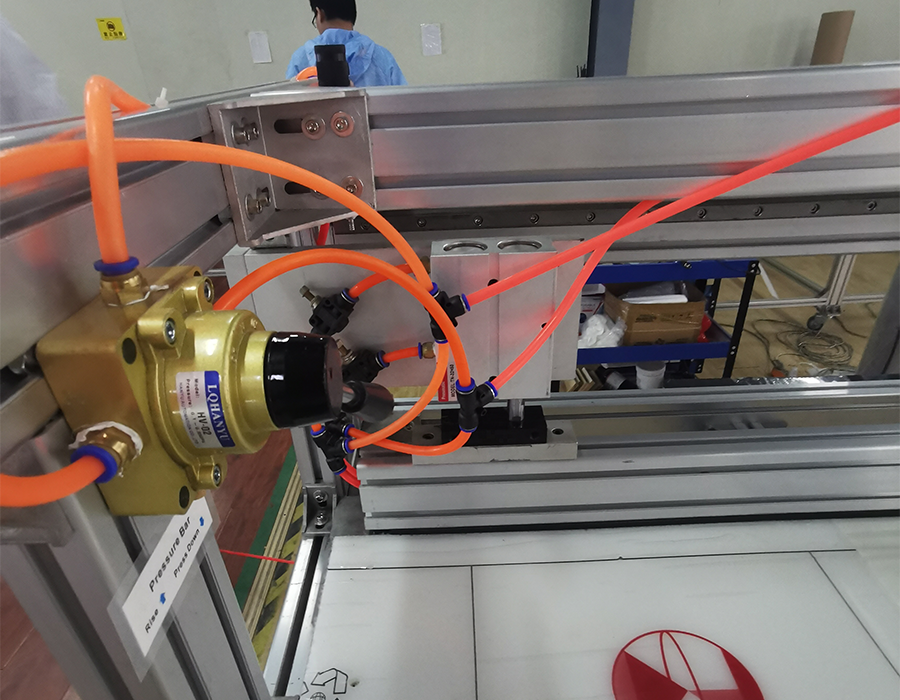

The main body of the machine is made of aluminum alloy, which is not only strong and durable but also resistant to corrosion. The clean and aesthetically pleasing design ensures that the machine performs reliably over time while maintaining a professional appearance. - Pneumatic Pressure Plate:

Equipped with a pneumatic pressure plate, the machine allows for quick and secure material fixation, improving cutting efficiency and reducing manual labor. The pneumatic system makes the operation safer and easier. - Wide Application Range:

The machine is suitable for cutting various materials, including smart film, plastic film, acrylic, PVC, and other soft or rigid materials, making it highly versatile across different industries.

Product Models and Specifications

| Model | Cutting Method | Max Cutting Width | Dimensions (mm) | Weight | Packaging Dimensions (mm) | Packaging Weight | Notes |

|---|---|---|---|---|---|---|---|

| QDCQT2200-3600 | Pneumatic Pressure Plate, Pneumatic Push Knife | 2200mm*3600mm | 4200mm2750mm1300mm | 320kg | 4050mm500mm600mm | 385kg | Customer-provided glass size: 10mm937.5mm2300mm*4 pieces |

| SDCQT2200-3600 | Pneumatic Pressure Plate, Manual Push Knife | 2200mm*3600mm | 4050mm2620mm1300mm | 305kg | 4050mm500mm600mm | 370kg | Customer-provided glass size: 10mm937.5mm2300mm*4 pieces |

| QDCQT1800-3600 | Pneumatic Pressure Plate, Pneumatic Push Knife | 1800mm*3600mm | 4200mm2400mm1300mm | 295kg | 4050mm500mm600mm | 360kg | Customer-provided glass size: 10mm937.5mm1950mm*4 pieces |

| SDCQT1800-3600 | Pneumatic Pressure Plate, Manual Push Knife | 1800mm*3600mm | 4050mm2280mm1300mm | 280kg | 4050mm500mm600mm | 345kg | Customer-provided glass size: 10mm937.5mm1950mm*4 pieces |

| SDC-3600 | Pneumatic Pressure Plate, Manual Push Knife | 3600mm | 3910mm460mm420mm | 115kg | 4000mm600mm600mm | 180kg | Customer-provided platform and glass |

| SDC-2800 | Pneumatic Pressure Plate, Manual Push Knife | 2800mm | 3110mm460mm420mm | 95kg | 3200mm600mm600mm | 142kg | Customer-provided platform and glass |

Shipping and Installation

- All machines are shipped in wooden crates to ensure safe transport.

- The listed prices do not include shipping and installation costs. Shipping and installation fees will be calculated based on the customer’s location and requirements.

Machine Advantages

- Precise Cutting, No Burrs or Delamination:

The precision cutting mechanism, combined with high-quality materials, ensures clean cuts with no burrs or delamination, maintaining the integrity of the film material. - Easy to Operate and Maintain:

The design of the upper and lower knives allows for quick replacement and easy adjustment, minimizing operational complexity. This ensures efficient production while reducing maintenance costs over time. - Efficient Pneumatic Operation:

The pneumatic pressure plate and push knife system enable quick and accurate material fixation, reducing manual intervention and improving cutting efficiency. The easy operation reduces the risk of human error and enhances workplace safety. - Durable and Long-Lasting:

Made with a robust aluminum alloy structure, the machine is resistant to corrosion and wear, ensuring long-lasting performance. It is built to withstand years of continuous operation with minimal maintenance. - Versatile and Multi-Material Compatibility:

The machine is designed to handle a variety of materials, including smart film, plastic sheets, acrylic, PVC, and more. It is ideal for industries ranging from electronics and automotive to construction and interior design. - Space-Saving and Optimized Production Line:

The compact design of the machine makes it suitable for various production environments, allowing businesses to optimize their workspace and improve overall production efficiency.

FAQs

How do I choose between smart film and smart glass?

When choosing between smart film and smart glass, consider the following factors:

- Application: Smart glass is ideal for new constructions or major renovations, while smart film can be retrofitted onto existing glass surfaces.

- Cost: Smart film is generally more cost-effective and easier to apply than smart glass.

- Aesthetics: Smart glass offers a seamless, integrated appearance, while smart film can be applied to a variety of glass types.

- Functionality: Both provide similar benefits, but smart glass may offer more advanced features and better long-term durability.

- Installation: Smart film is easier and quicker to install, whereas smart glass may require professional installation.

Evaluate your specific needs, budget, and installation requirements to make the best choice.

Can smart film/smart glass be customized in size?

Yes, both our smart films and smart glass can be customized to meet specific customer needs, including size, shape and functional configuration. For smart films, you only need to provide the actual size or visible light size of the glass. For custom smart glass, we need you to provide details such as upper and lower groove depth, left and right groove depth, groove width, and visible light size of the glass.

How can smart glass and smart film be controlled? Can they be integrated with smart home systems?

Smart glass and smart film can be controlled in several ways, including wall switches, remote controls, or integration with smart home systems. When integrated with a smart home system, you can control the transparency and other features through mobile apps or voice commands using platforms like Google Assistant, Apple HomeKit, or Amazon Alexa.

Our products currently support the following smart home platforms and protocols:

- Matter

- Esupport Works with Everything

- eWeLink

- Works with Google Home

- Works with Apple Home

- Works with Alexa

- Zigbee

- Tuya

These versatile control options allow smart glass and smart film to seamlessly integrate into your smart home environment, providing convenience and flexibility.

What payment methods do you accept?

We support payments through local accounts in over 20 countries, accept more than 50 currencies, and facilitate transactions in over 100 countries. This ensures secure and efficient payment options for our global customers. We accept various payment methods including Visa, MasterCard, American Express, Discover, PayPal, JCB, Diners Club, and UnionPay. For more details or specific payment inquiries, please contact us.

What are your shipping options and delivery times?

We offer air, land, and sea freight options based on your location. Delivery times depend on the order volume, with smaller orders typically shipping within 1-2 days. For precise shipping times and options, please contact us with your specific requirements.