Smart Glass Co., Ltd. —— China's leading PDLC film manufacturer

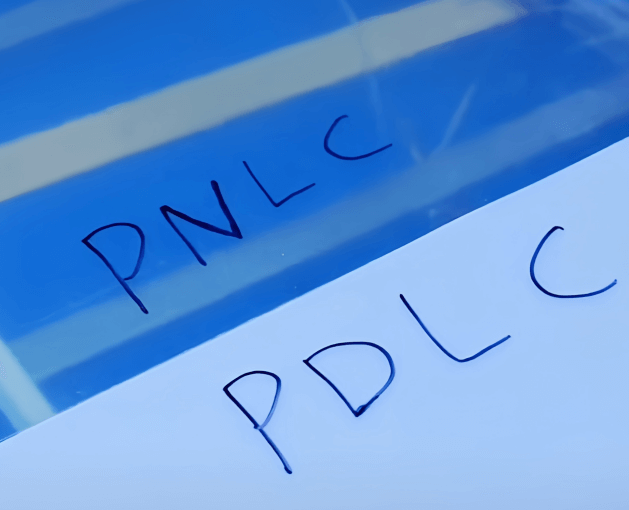

Reverse Smart Film(PNLC)★

PRODUCT PARAMETERS

Description

FAQs

Request A Quote

Description

Reverse Smart Film(PNLC)

The film consists of two outer layers of polyester film (PET), internally coated with a transparent conductive layer. A layer of REVERSE-PNLC is sandwiched between the two PET substrates. Placed inside glazing by means of the oven lay-up process, switchable REVERSE PNLC film allows the colour of the glass and, at the same time, the intensity of the passage of sunlight to be varied by means of a simple electrical control.

PNLC smart film is a special type of privacy glass that works a little differently than most. Unlike regular smart film, PNLC film is clear when there’s no electricity running to it. This makes it a great option for car windows – you can flick a switch and instantly get privacy without blocking the view when you don’t need it. It’s a new technology, so the price tag is still a bit high, but it’s becoming more affordable. We offer PNLC film in two ways: as an adhesive film that applies existing glass, or laminated between two panes of glass for a more permanent solution.

Working principle of Reverse Smart Film(PNLC):

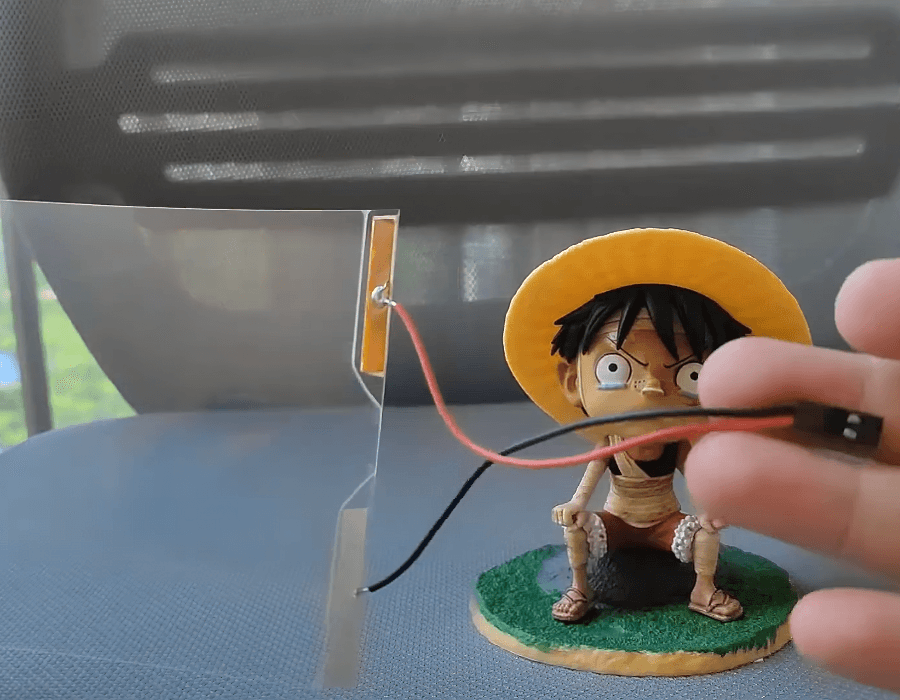

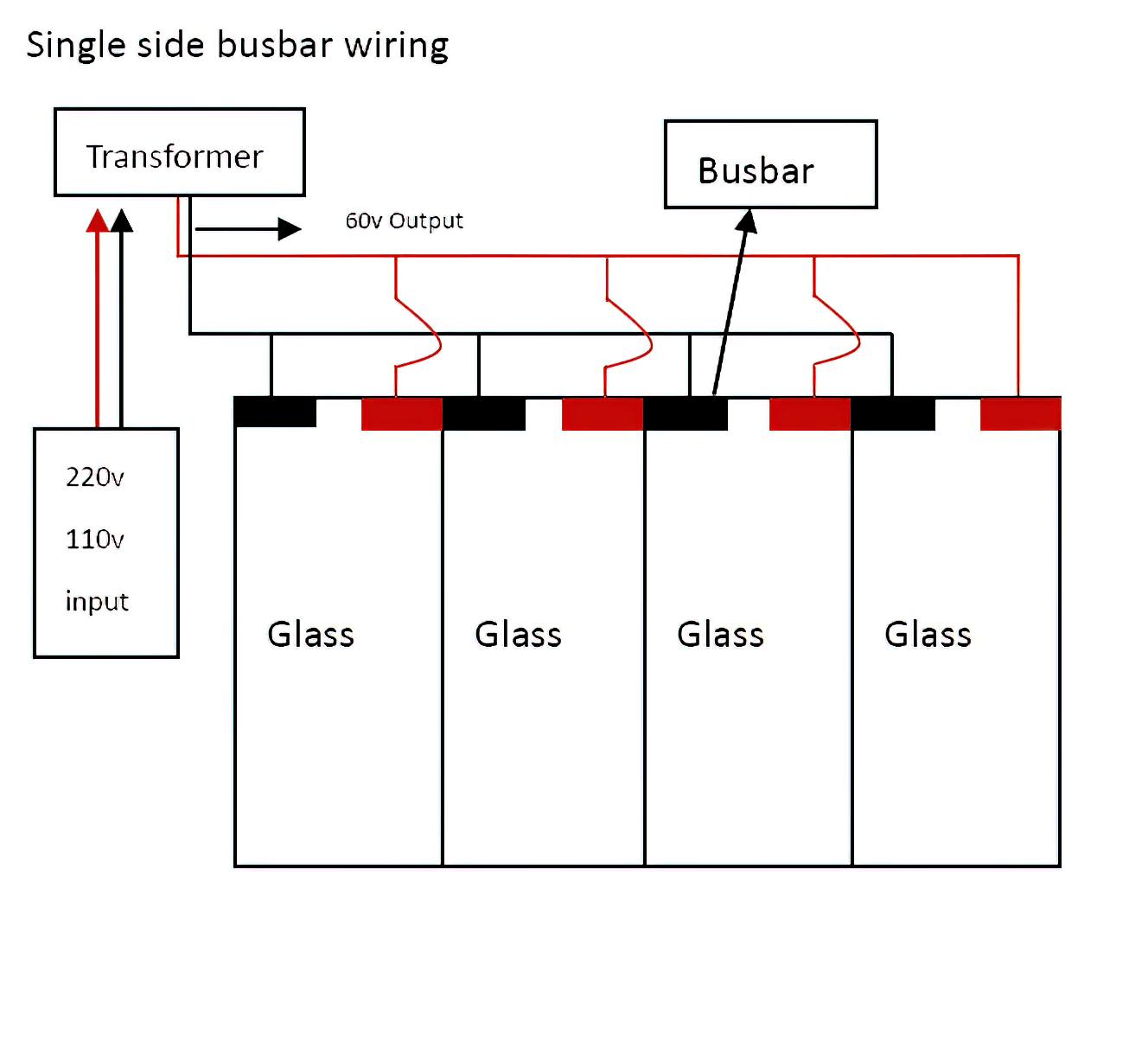

Reverse Smart Film(PNLC) electrode wiring method:

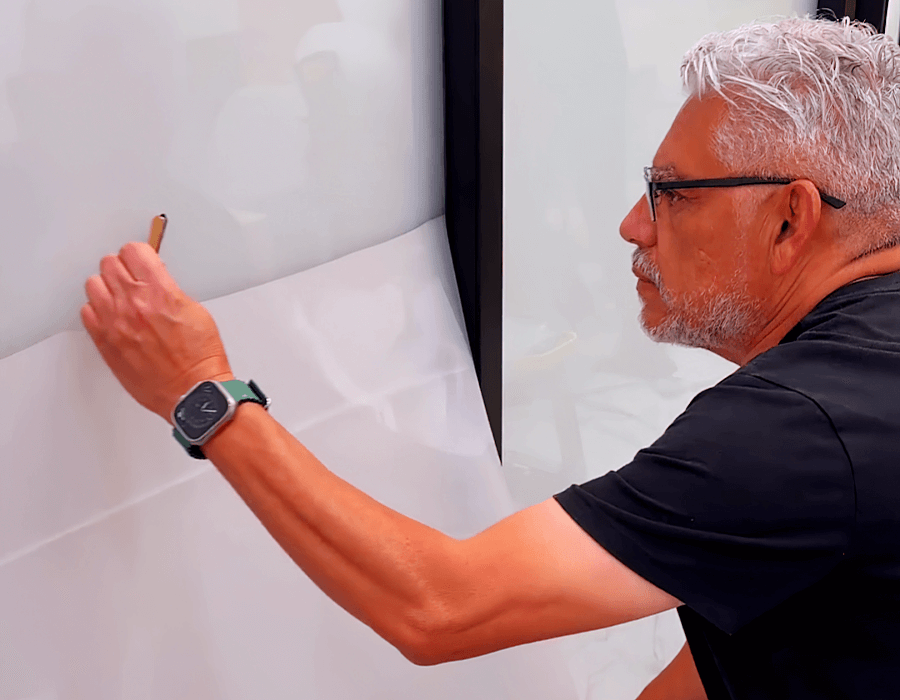

Reverse Smart Film(PNLC) Installation Instructions

1. Prepare the Glass Surface

- Clean the glass surface thoroughly to remove any dust, dirt, or grease. Use a lint-free cloth and a mild glass cleaner for the best results.

- Ensure the surface is completely dry before proceeding with the application.

2. Measure and Cut the Film (if necessary)

- Measure the dimensions of the glass where the film will be applied.

- If needed, cut the self-adhesive film to fit the glass surface. Ensure the edges are smooth and even.

3. Peel Off the Backing Paper

- Carefully peel off the backing paper from the film, starting from one corner. Take care not to touch the adhesive side of the film to avoid contamination.

4. Apply the Film to the Glass

- Align the film with the top edge of the glass and gently place it onto the surface.

- Slowly smooth the film downwards, pressing it onto the glass to avoid air bubbles.

- Use a soft cloth or squeegee to ensure full adhesion, starting from the center and working outwards to the edges.

5. Remove Air Bubbles

- If any air bubbles remain, use a small needle or pin to puncture them and then smooth them out using the squeegee or cloth.

6. Connect the Film to Power

- Connect the electrode wires of the film to the power source. Follow the manufacturer’s instructions for proper connection to ensure the film functions correctly.

- Ensure all electrical connections are secure and insulated.

7. Test the Film

- Turn on the power and use the provided controller to toggle the film between its transparent and opaque states.

- Check for any imperfections in the film’s operation, such as uneven transitions or lack of response to the controller.

Applications:

Contact Us:

For more information, product specifications, or custom size requests, please feel free to contact us. Our team is ready to assist with tailored solutions to meet your specific needs and project goals.

FAQs

How do I choose between smart film and smart glass?

When choosing between smart film and smart glass, consider the following factors:

- Application: Smart glass is ideal for new constructions or major renovations, while smart film can be retrofitted onto existing glass surfaces.

- Cost: Smart film is generally more cost-effective and easier to apply than smart glass.

- Aesthetics: Smart glass offers a seamless, integrated appearance, while smart film can be applied to a variety of glass types.

- Functionality: Both provide similar benefits, but smart glass may offer more advanced features and better long-term durability.

- Installation: Smart film is easier and quicker to install, whereas smart glass may require professional installation.

Evaluate your specific needs, budget, and installation requirements to make the best choice.

Can smart film/smart glass be customized in size?

Yes, both our smart films and smart glass can be customized to meet specific customer needs, including size, shape and functional configuration. For smart films, you only need to provide the actual size or visible light size of the glass. For custom smart glass, we need you to provide details such as upper and lower groove depth, left and right groove depth, groove width, and visible light size of the glass.

How can smart glass and smart film be controlled? Can they be integrated with smart home systems?

Smart glass and smart film can be controlled in several ways, including wall switches, remote controls, or integration with smart home systems. When integrated with a smart home system, you can control the transparency and other features through mobile apps or voice commands using platforms like Google Assistant, Apple HomeKit, or Amazon Alexa.

Our products currently support the following smart home platforms and protocols:

- Matter

- Esupport Works with Everything

- eWeLink

- Works with Google Home

- Works with Apple Home

- Works with Alexa

- Zigbee

- Tuya

These versatile control options allow smart glass and smart film to seamlessly integrate into your smart home environment, providing convenience and flexibility.

What payment methods do you accept?

We support payments through local accounts in over 20 countries, accept more than 50 currencies, and facilitate transactions in over 100 countries. This ensures secure and efficient payment options for our global customers. We accept various payment methods including Visa, MasterCard, American Express, Discover, PayPal, JCB, Diners Club, and UnionPay. For more details or specific payment inquiries, please contact us.

What are your shipping options and delivery times?

We offer air, land, and sea freight options based on your location. Delivery times depend on the order volume, with smaller orders typically shipping within 1-2 days. For precise shipping times and options, please contact us with your specific requirements.